- Introduction to laser cleaning technology

- Advantages of using laser cleaning for removing contaminants

- Types of contaminants that can be removed with laser cleaning

- Importance of proper training for operators using laser cleaning equipment

- Regulatory requirements for using laser cleaning in different industries

- Impact of laser cleaning on reducing downtime in production processes

- Challenges of cleaning delicate surfaces with laser technology

- Role of laser cleaning in the maintenance of power plants

Introduction to laser cleaning technology

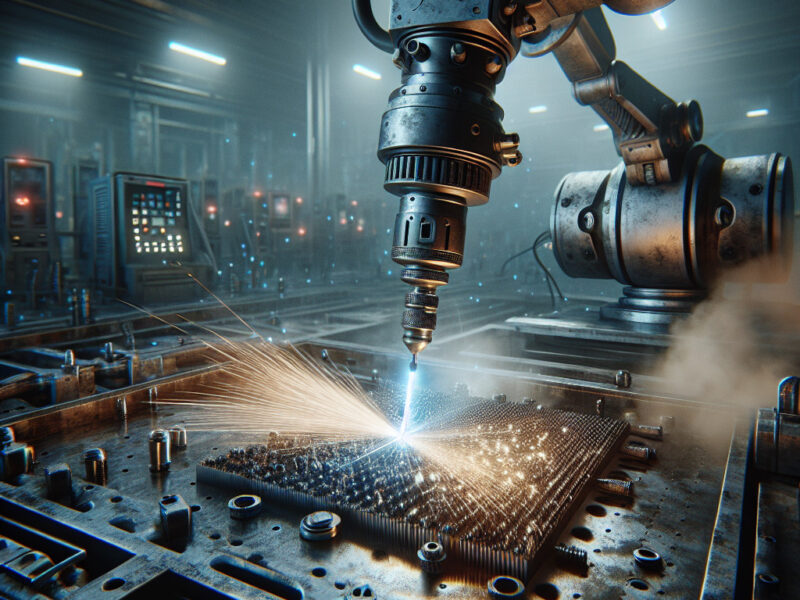

How Laser Cleaning Works

Laser cleaning works by focusing a high-energy laser beam onto the surface of the material to be cleaned. The intense heat generated by the laser vaporizes the contaminants, leaving behind a clean surface. This process is highly precise and can be adjusted to remove specific types of contaminants without damaging the underlying material.

Benefits of Laser Cleaning

- Non-contact cleaning: Laser cleaning does not require physical contact with the surface, reducing the risk of damage.

- Environmentally friendly: Laser cleaning does not produce any harmful chemicals or waste, making it an eco-friendly option.

- Cost-effective: While the initial investment in laser cleaning technology may be higher, the long-term savings in labor and materials make it a cost-effective solution.

Applications of Laser Cleaning

Laser cleaning technology is used in a wide range of industries, including:

- Automotive: Laser cleaning is used to remove rust, paint, and other contaminants from car parts.

- Aerospace: Laser cleaning is used to clean turbine blades, engine components, and other critical parts.

- Historical preservation: Laser cleaning is used to remove dirt and grime from delicate artifacts without causing damage.

Overall, laser cleaning technology offers a versatile and efficient solution for removing contaminants from a variety of surfaces. Its precision and effectiveness make it a valuable tool for industries looking to improve their cleaning processes.

#laser #cleaning #technology #innovation #precision #efficiency

#removingcontaminants #coatings #oxides #noncontactcleaning #environmentallyfriendly #costeffective

Advantages of using laser cleaning for removing contaminants

Advantages of laser cleaning:

| Advantage | Description |

|---|---|

| Non-contact | Laser cleaning does not require physical contact with the surface, reducing the risk of damage. |

| Precision | Laser beams can be precisely controlled to target specific areas, ensuring thorough cleaning. |

| No chemicals | Laser cleaning is a chemical-free process, making it environmentally friendly. |

| No residue | Unlike chemical cleaning, laser cleaning leaves no residue behind on the surface. |

| Efficiency | Laser cleaning is a fast and efficient method, saving time and labor costs. |

Overall, laser cleaning offers a number of advantages that make it a preferred method for removing contaminants from surfaces. Its non-contact nature, precision, lack of chemicals, absence of residue, and efficiency make it a versatile and effective cleaning solution.

#laser #cleaning #contaminants #advantages #precision #efficiency

Keywords: laser cleaning, contaminants, advantages, precision, efficiency

Long-tail phrases: advantages of using laser cleaning, benefits of laser cleaning, laser cleaning for surface cleaning, advantages of non-contact cleaning.

Types of contaminants that can be removed with laser cleaning

- Rust: Laser cleaning can easily remove rust from metal surfaces, restoring them to their original condition.

- Paint: Paint can be quickly and efficiently removed with laser cleaning, without damaging the underlying surface.

- Oil and grease: Laser cleaning is effective at removing oil and grease from surfaces, making it ideal for cleaning machinery and equipment.

- Corrosion: Laser cleaning can remove corrosion from metal surfaces, extending their lifespan and preventing further damage.

- Scale: Scale buildup on surfaces can be easily removed with laser cleaning, improving the efficiency of equipment.

- Adhesives: Laser cleaning can effectively remove adhesives from surfaces, making it easier to reapply new adhesives or coatings.

Overall, laser cleaning is a versatile and efficient method for removing a wide range of contaminants from various surfaces. Whether you need to clean metal, plastic, glass, or other materials, laser cleaning can provide a fast and effective solution.

Some of the key benefits of laser cleaning include:

- Non-contact cleaning: Laser cleaning does not require physical contact with the surface, reducing the risk of damage.

- Environmentally friendly: Laser cleaning does not use any chemicals or solvents, making it a safe and eco-friendly cleaning method.

- Precision cleaning: Laser cleaning can be controlled with high precision, allowing for targeted cleaning of specific areas.

- Cost-effective: While the initial investment in laser cleaning equipment may be higher, the long-term cost savings can be significant due to reduced maintenance and cleaning time.

In conclusion, laser cleaning is a highly effective method for removing a wide range of contaminants from various surfaces. Whether you need to remove rust, paint, oil, or other types of contaminants, laser cleaning can provide a fast, efficient, and environmentally friendly solution.

#laser #cleaning #contaminants #rust #paint #oil #grease #corrosion #scale #adhesives

frazy kluczowe:

– Effective method for removing contaminants

– Versatile and efficient cleaning technology

– Non-contact and precision cleaning

– Environmentally friendly and cost-effective solution

Importance of proper training for operators using laser cleaning equipment

- 1. Safety: Laser cleaning equipment emits high-powered laser beams that can cause serious injury if not used properly. Operators must be trained on how to safely operate the equipment and follow all safety protocols.

- 2. Efficiency: Proper training can help operators maximize the efficiency of the laser cleaning process, ensuring that surfaces are cleaned effectively in a timely manner.

- 3. Maintenance: Operators who are properly trained can also perform basic maintenance tasks on the equipment, helping to prolong its lifespan and prevent costly repairs.

- 4. Quality control: Training can help operators ensure that surfaces are cleaned to the desired standard, reducing the risk of rework or customer complaints.

Overall, proper training for operators using laser cleaning equipment is crucial for ensuring safety, efficiency, and quality control in the cleaning process.

Keywords: laser cleaning equipment, operators, training, safety, efficiency, maintenance, quality control

Long-tail phrases: importance of proper training for operators, laser cleaning equipment safety, efficiency in cleaning process

#laser #cleaning #equipment #operators #training #safety #efficiency #maintenance #qualitycontrol

#importanceofpropertrainingforoperators #lasercleaningequipmentsafety #efficiencyincleaningprocess

Regulatory requirements for using laser cleaning in different industries

Health and safety regulations

One of the primary concerns when using lasers for cleaning purposes is the potential health hazards associated with exposure to laser radiation. In order to protect workers from these risks, industries must adhere to strict safety regulations that govern the use of lasers in the workplace.

- Workers must be provided with appropriate personal protective equipment, such as laser safety goggles, to prevent eye injuries.

- Proper training on laser safety protocols must be provided to all employees who will be working with laser cleaning equipment.

- Regular monitoring of laser emissions and maintenance of equipment is essential to ensure that exposure levels remain within safe limits.

Environmental regulations

In addition to health and safety concerns, industries using laser cleaning technology must also comply with environmental regulations to minimize the impact of their operations on the environment.

- Proper disposal of waste materials generated during the cleaning process is essential to prevent contamination of soil and water sources.

- Effluent emissions from laser cleaning equipment must be monitored and controlled to prevent air pollution.

- Industries may be required to obtain permits or licenses from regulatory authorities to use lasers for cleaning purposes.

Conclusion

Overall, the use of laser cleaning technology in different industries is subject to a range of regulatory requirements aimed at ensuring the safety of workers and protecting the environment. By adhering to these regulations, industries can harness the benefits of laser cleaning while minimizing the risks associated with its use.

#laser #cleaning #regulations #safety #environmental #compliance

frazy kluczowe:

– regulatory requirements for laser cleaning

– laser cleaning in different industries

– health and safety regulations for laser cleaning

– environmental regulations for laser cleaning

– compliance with laser cleaning standards

Impact of laser cleaning on reducing downtime in production processes

Another advantage of laser cleaning is its precision and effectiveness in removing even the toughest contaminants. Whether it’s rust, paint, grease, or other stubborn residues, laser cleaning can effectively and efficiently remove them without damaging the underlying surface. This ensures that equipment remains in optimal condition, reducing the need for costly repairs and replacements.

Furthermore, laser cleaning is a non-contact and non-abrasive process, making it safe for use on a wide range of materials and surfaces. This versatility allows businesses to use laser cleaning in a variety of applications, from delicate electronics to heavy machinery, without the risk of damage or wear and tear.

In conclusion, the impact of laser cleaning on reducing downtime in production processes cannot be overstated. By offering a fast, efficient, and cost-effective solution to traditional cleaning methods, laser cleaning has become an invaluable tool for industries looking to improve their maintenance practices and increase productivity.

- Increased productivity

- Cost savings

- Efficiency

- Precision cleaning

- Versatility

- #laser

- #cleaning

- #production

- #downtime

- #efficiency

Reducing downtime in production processes with laser cleaning technology

Challenges of cleaning delicate surfaces with laser technology

Challenges:

- Sensitivity: Delicate surfaces can be sensitive to heat and pressure, which can make traditional cleaning methods ineffective or damaging. Laser technology must be carefully calibrated to avoid causing damage to the surface.

- Precision: Laser cleaning requires a high level of precision to ensure that only the surface contaminants are removed without damaging the underlying material. This level of precision can be difficult to achieve, especially on complex surfaces.

- Material compatibility: Not all materials are suitable for laser cleaning. Some materials may absorb the laser energy, leading to damage or discoloration. It is important to test the compatibility of the material before using laser technology for cleaning.

- Cost: Laser cleaning equipment can be expensive to purchase and maintain. The initial investment and ongoing maintenance costs can be a barrier for some businesses looking to adopt this technology for cleaning delicate surfaces.

- Safety: Laser technology can pose safety risks if not used properly. Operators must be trained in the safe use of laser cleaning equipment to prevent accidents and injuries.

Keywords:

Laser technology, delicate surfaces, cleaning, challenges, sensitivity, precision, material compatibility, cost, safety

Long-tail phrases:

Challenges of cleaning delicate surfaces with laser technology, precision in laser cleaning, material compatibility in laser cleaning, safety considerations in laser cleaning

#laser #cleaning #delicate #surfaces #technology #challenges #sensitivity #precision #material #compatibility #cost #safety #longtailphrases #keywords

Role of laser cleaning in the maintenance of power plants

Efficiency and precision

Laser cleaning uses a focused laser beam to remove contaminants from surfaces without damaging the underlying material. This process is highly precise and can target specific areas without affecting surrounding components. The ability to control the intensity and duration of the laser beam allows for customized cleaning solutions for different types of contaminants.

Environmental benefits

Unlike traditional cleaning methods that use harsh chemicals or abrasive materials, laser cleaning is a non-contact and chemical-free process. This reduces the generation of hazardous waste and minimizes the impact on the environment. Additionally, laser cleaning does not produce secondary waste products, making it a more sustainable cleaning solution for power plants.

Cost-effectiveness

Although the initial investment in laser cleaning equipment may be higher than traditional cleaning methods, the long-term cost savings can be significant. Laser cleaning is a faster and more efficient process, reducing downtime and labor costs associated with maintenance. The precision of laser cleaning also helps to extend the lifespan of critical components, reducing the need for frequent replacements.

Applications in power plants

Laser cleaning can be used in a variety of applications within power plants, including the removal of rust, scale, and paint from boilers, turbines, and heat exchangers. It can also be used for cleaning electrical components, such as insulators and connectors, to improve performance and prevent electrical failures. The versatility and effectiveness of laser cleaning make it an essential tool for maintaining the efficiency and reliability of power plants.

Conclusion

Laser cleaning offers a more efficient, environmentally friendly, and cost-effective solution for maintaining power plants. By utilizing laser technology, power plant operators can improve the performance and reliability of their facilities while reducing the impact on the environment. As the demand for clean energy continues to grow, laser cleaning will play an increasingly important role in the maintenance of power plants.

- efficiency

- precision

- environmental benefits

- cost-effectiveness

- applications

- laser cleaning in power plants

- environmentally friendly maintenance

- cost savings in maintenance

- precision cleaning solutions

- improved performance and reliability

#cleanenergy #powerplants #laser #maintenance #environment #efficiency

- Sure! Here are some questions related to Software House Poland in blockchain development: - 29 September 2025

- Laser cleaning for removing contaminants from hard-to-reach surfaces - 1 March 2024

- The difference between B2B and B2C e-commerce - 29 February 2024