- The history of laser cleaning technology

- Types of lasers used for paint removal

- Challenges faced in implementing laser cleaning technology

- The role of laser cleaning in the automotive industry

- The role of laser cleaning in the marine industry

- The role of laser cleaning in the electronics industry

- The role of laser cleaning in the food processing industry

- The role of laser cleaning in the automotive restoration industry

The history of laser cleaning technology

Early developments

In the 1960s, the first lasers were developed for industrial applications. These early lasers were primarily used for cutting and welding metals, but researchers soon realized that they could also be used for cleaning surfaces. The first laser cleaning systems were developed in the 1980s, using pulsed lasers to remove contaminants from surfaces without damaging them.

The evolution of laser cleaning technology

Over the years, laser cleaning technology has continued to evolve and improve. Today, there are a variety of laser cleaning systems available, each designed for specific applications. Some systems use continuous wave lasers, while others use pulsed lasers for more precise cleaning.

- Laser cleaning technology has been used in a wide range of industries, from aerospace to automotive.

- One of the key advantages of laser cleaning is its ability to remove contaminants without the need for harsh chemicals.

- Some laser cleaning systems can even be used underwater, making them ideal for cleaning ship hulls and other submerged surfaces.

The future of laser cleaning technology

As technology continues to advance, we can expect to see even more innovations in laser cleaning technology. Researchers are currently working on developing more powerful lasers that can clean surfaces more quickly and efficiently. Additionally, new applications for laser cleaning technology are constantly being discovered, making it an essential tool for industries around the world.

- laser

- cleaning

- technology

- history

- evolution

- industrial

- applications

- advantages

- future

laser cleaning, technology history, industrial applications, future advancements, surface cleaning

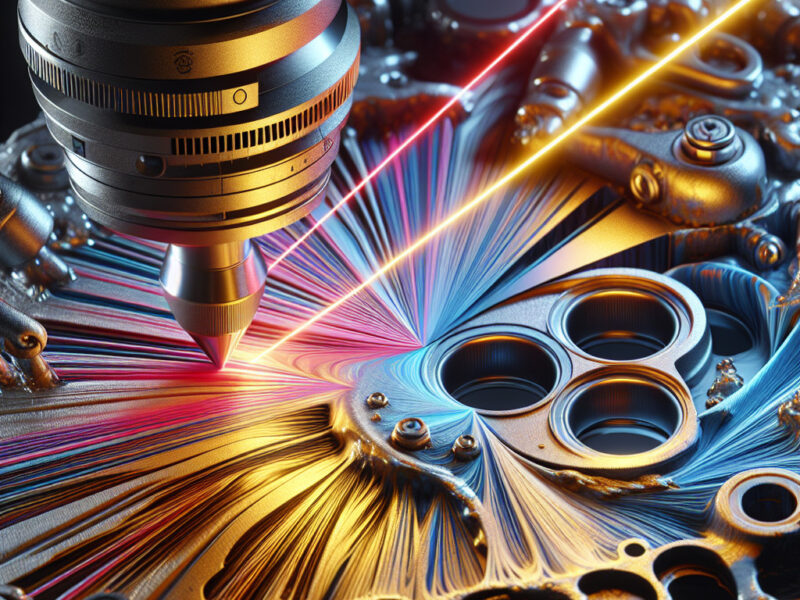

Types of lasers used for paint removal

1. CO2 lasers

CO2 lasers are one of the most commonly used types of lasers for paint removal. These lasers emit a high-powered beam of infrared light that is absorbed by the paint, causing it to vaporize and be removed from the surface. CO2 lasers are effective for removing both organic and inorganic paints, making them a versatile option for paint removal projects.

2. Nd:YAG lasers

Nd:YAG lasers are another popular choice for paint removal. These lasers use a crystal medium to generate a high-energy beam of light that can effectively remove paint from surfaces. Nd:YAG lasers are particularly useful for removing thick layers of paint or paint that is resistant to other methods of removal.

3. Excimer lasers

Excimer lasers are a type of ultraviolet laser that is commonly used for precision paint removal. These lasers emit a short pulse of high-energy light that can remove paint without damaging the underlying surface. Excimer lasers are often used for delicate paint removal projects where precision is key.

4. Fiber lasers

Fiber lasers are a newer type of laser that is gaining popularity for paint removal. These lasers use optical fibers to deliver a high-powered beam of light that can quickly and efficiently remove paint from surfaces. Fiber lasers are known for their precision and speed, making them a great option for large-scale paint removal projects.

5. Diode lasers

Diode lasers are a compact and cost-effective option for paint removal. These lasers use semiconductor diodes to generate a high-energy beam of light that can effectively remove paint from surfaces. Diode lasers are often used for smaller paint removal projects or for touch-up work.

6. Pulsed lasers

Pulsed lasers are a type of laser that emits short pulses of high-energy light. These lasers are often used for paint removal projects where precision and control are important. Pulsed lasers can be adjusted to remove paint at different depths, making them a versatile option for a variety of paint removal tasks.

7. UV lasers

UV lasers are a type of laser that emits ultraviolet light, which is particularly effective for removing certain types of paint. UV lasers are often used for paint removal projects where other types of lasers may not be as effective. These lasers are known for their ability to remove paint without damaging the underlying surface.

8. Green lasers

Green lasers are a type of laser that emits a green-colored beam of light. These lasers are often used for paint removal projects where precision and visibility are important. Green lasers are particularly effective for removing paint from surfaces that are difficult to access or see, making them a versatile option for a variety of paint removal tasks.

Conclusion

There are several types of lasers that are commonly used for paint removal, each with its own unique characteristics and benefits. Whether you are dealing with thick layers of paint or delicate surfaces, there is a laser option that can meet your specific needs. By choosing the right type of laser for your paint removal project, you can save time and effort while achieving professional results.

- CO2 lasers

- Nd:YAG lasers

- Excimer lasers

- Fiber lasers

- Diode lasers

- Pulsed lasers

- UV lasers

- Green lasers

#paintremoval #lasers #types #technology #CO2 #NdYAG #Excimer #Fiber #Diode #Pulsed #UV #Green

Challenges faced in implementing laser cleaning technology

1. Cost

One of the main challenges faced in implementing laser cleaning technology is the high cost associated with purchasing and maintaining the equipment. Laser cleaning machines can be expensive to buy and require regular maintenance to ensure they are functioning properly. This cost can be a barrier for smaller businesses or industries with limited budgets.

2. Safety

Another challenge is ensuring the safety of workers when using laser cleaning technology. Laser beams can be harmful to the eyes and skin if proper precautions are not taken. It is important to provide training to employees on how to safely operate the equipment and use protective gear to prevent any accidents or injuries.

3. Compatibility

Not all surfaces are suitable for laser cleaning technology. Some materials may be damaged or altered by the intense heat generated by the laser beam. It is important to test the compatibility of different surfaces before using laser cleaning technology to avoid any damage or unwanted effects.

4. Precision

Laser cleaning technology requires a high level of precision to effectively remove contaminants without damaging the surface underneath. It can be challenging to control the intensity and focus of the laser beam to ensure that only the contaminants are removed while preserving the integrity of the surface.

5. Environmental impact

There are concerns about the environmental impact of using laser cleaning technology. The energy consumption and emissions generated by the equipment can contribute to air and noise pollution. It is important to consider the environmental implications of using this technology and implement measures to minimize its impact.

| Challenge | Description |

|---|---|

| Cost | High cost of equipment and maintenance |

| Safety | Risk of eye and skin injuries |

| Compatibility | Not suitable for all surfaces |

| Precision | Requires high level of precision |

| Environmental impact | Concerns about energy consumption and emissions |

Overall, implementing laser cleaning technology can be a complex process that requires careful consideration of various factors. By addressing these challenges and finding solutions, industries can benefit from the efficiency and effectiveness of this technology in removing contaminants from surfaces.

#laser #cleaning #technology #challenges #cost #safety #compatibility #precision #environmental impact, efficiency, contaminants, surfaces, industries, equipment, maintenance, safety precautions, laser beam, precision control, environmental implications, air pollution, noise pollution.

The role of laser cleaning in the automotive industry

Benefits of laser cleaning in the automotive industry

One of the main advantages of laser cleaning is its ability to remove contaminants and coatings with precision and control. Traditional methods such as sandblasting or chemical cleaning can be abrasive and may damage the surface of the vehicle. Laser cleaning, on the other hand, can be adjusted to target specific areas without affecting the surrounding material.

Another benefit of laser cleaning is its environmental friendliness. Unlike chemical cleaning agents, lasers do not produce harmful fumes or waste products. This makes laser cleaning a sustainable and eco-friendly option for automotive manufacturers looking to reduce their environmental impact.

Additionally, laser cleaning is a fast and efficient process. It can be automated to clean large areas quickly, saving time and labor costs. This is especially important in the automotive industry, where production schedules are tight and efficiency is key to meeting demand.

Role of laser cleaning in improving efficiency and quality

Laser cleaning plays a crucial role in improving efficiency and quality in the automotive industry. By removing contaminants and coatings with precision, laser cleaning ensures that surfaces are clean and ready for further processing. This results in higher quality finished products and reduces the risk of defects or rework.

Furthermore, laser cleaning can be used to prepare surfaces for painting or coating. By removing old paint or rust, laser cleaning creates a clean and smooth surface for new coatings to adhere to. This improves the durability and longevity of the finish, resulting in a higher quality product for consumers.

Overall, laser cleaning is a versatile and effective method for maintaining cleanliness and quality in the automotive industry. Its precision, efficiency, and environmental friendliness make it a valuable tool for manufacturers looking to improve their processes and products.

| Keyword | Definition |

|---|---|

| Laser cleaning | A non-contact method for removing contaminants and coatings using high-powered lasers |

| Automotive industry | The sector of the economy that designs, manufactures, and sells vehicles |

| Efficiency | The ability to achieve maximum productivity with minimum wasted effort or expense |

hashtags: #laser #cleaning #automotive #industry

Keywords: laser cleaning, automotive industry, efficiency

Long-tail phrases: role of laser cleaning in improving efficiency and quality in the automotive industry, benefits of laser cleaning in the automotive industry

The role of laser cleaning in the marine industry

Benefits of laser cleaning in the marine industry:

– 🌊 Efficient removal of rust, paint, and other contaminants

– 🌊 Non-contact cleaning method that minimizes damage to surfaces

– 🌊 Environmentally friendly process that eliminates the need for harsh chemicals

– 🌊 Cost-effective solution that reduces downtime and labor costs

– 🌊 Improved safety for workers by reducing exposure to hazardous materials

Applications of laser cleaning in the marine industry:

– 🚢 Ship hull cleaning to improve fuel efficiency and reduce drag

– 🚢 Removal of marine growth to prevent corrosion and biofouling

– 🚢 Cleaning of engine components to maintain optimal performance

– 🚢 Restoration of historical ships and artifacts for preservation

With its precision and versatility, laser cleaning has become an indispensable tool for shipyards and marine maintenance facilities. By harnessing the power of laser technology, the marine industry can achieve higher standards of cleanliness, efficiency, and sustainability.

Hashtags: #marineindustry #lasercleaning #shipmaintenance

Keywords: laser cleaning, marine industry, efficiency, sustainability, ship maintenance

Long-tail phrases: laser cleaning technology in ship maintenance, benefits of laser cleaning in marine industry, applications of laser cleaning on ships

—

marineindustry, lasercleaning, shipmaintenance, laser cleaning, marine industry, efficiency, sustainability, ship maintenance, laser cleaning technology in ship maintenance, benefits of laser cleaning in marine industry, applications of laser cleaning on ships

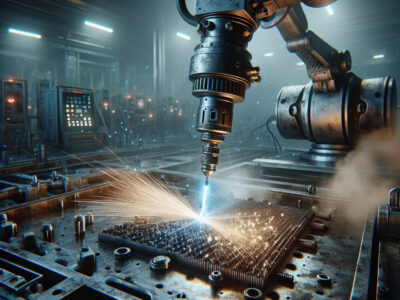

The role of laser cleaning in the electronics industry

Benefits of laser cleaning in the electronics industry

One of the main benefits of laser cleaning is its ability to remove contaminants from delicate electronic components without causing any damage. This is crucial in the manufacturing process, where even the smallest amount of debris can lead to malfunctions or failures. Laser cleaning also eliminates the need for harsh chemicals or abrasive methods, making it a more environmentally friendly option.

Applications of laser cleaning in the electronics industry

Laser cleaning is used in a variety of applications in the electronics industry, including:

| Application | Description |

|---|---|

| PCB cleaning | Removing flux residues and other contaminants from printed circuit boards. |

| Component cleaning | Cleaning electronic components such as connectors, switches, and sensors. |

| Mold cleaning | Removing mold release agents from injection molds used in manufacturing. |

Future developments in laser cleaning technology

As technology continues to advance, we can expect to see further developments in laser cleaning technology. This may include improvements in laser power and efficiency, as well as the development of new laser cleaning techniques for specific applications in the electronics industry.

Conclusion

Laser cleaning plays a crucial role in the electronics industry by providing a precise and efficient method for removing contaminants from surfaces. Its benefits include damage-free cleaning, environmental friendliness, and versatility in various applications. As technology continues to evolve, we can expect to see further advancements in laser cleaning technology that will further enhance its role in the electronics industry.

#laser #cleaning #electronics #industry #technology #precision #efficiency #contaminants #applications #PCB #components #mold #future #developments #advancements #environmentallyfriendly #versatility

frazy kluczowe:

– Importance of laser cleaning in electronics manufacturing

– Benefits of laser cleaning for delicate components

– Applications of laser cleaning in PCB manufacturing

– Future developments in laser cleaning technology for electronics

– Precision and efficiency of laser cleaning in the electronics industry

The role of laser cleaning in the food processing industry

The benefits of laser cleaning in the food processing industry are numerous. Firstly, laser cleaning is a dry process, which means that there is no need for water or chemicals, reducing the environmental impact of cleaning operations. Secondly, laser cleaning is highly precise and can target specific areas without affecting surrounding surfaces. This precision ensures that contaminants are completely removed, reducing the risk of foodborne illnesses and product recalls. Additionally, laser cleaning is a fast process, allowing for quick turnaround times and increased productivity in food processing facilities.

Some of the applications of laser cleaning in the food processing industry include cleaning conveyor belts, food processing equipment, packaging machinery, and storage tanks. Laser cleaning can effectively remove residues such as oils, fats, proteins, and sugars that can build up on surfaces over time. By maintaining a clean and hygienic environment, food processing facilities can comply with strict food safety regulations and ensure the quality of their products.

- Laser cleaning is a cutting-edge technology that offers a more efficient and environmentally friendly solution for cleaning equipment and surfaces in the food processing industry.

- Laser cleaning is non-contact and non-abrasive, making it suitable for delicate equipment and surfaces.

- The benefits of laser cleaning in the food processing industry include reduced environmental impact, increased precision, and faster cleaning times.

- Applications of laser cleaning in the food processing industry include cleaning conveyor belts, food processing equipment, packaging machinery, and storage tanks.

Overall, laser cleaning plays a crucial role in maintaining cleanliness and hygiene in the food processing industry. By adopting this advanced technology, food processing facilities can improve their efficiency, reduce the risk of contamination, and ensure the safety and quality of their products.

Hashtags: #foodprocessing #laser cleaning #hygiene #safety

Keywords: food processing, laser cleaning, hygiene, safety, contamination

Long-tail phrases: advanced technology for cleaning, environmentally friendly solution, food safety regulations compliance

The role of laser cleaning in the automotive restoration industry

Benefits of laser cleaning in automotive restoration

There are several key benefits to using laser cleaning in the automotive restoration industry. Some of the most notable advantages include:

| Benefit | Description |

|---|---|

| Non-abrasive | Laser cleaning does not require harsh chemicals or abrasive materials, making it a gentle and safe method for restoring delicate automotive parts. |

| Precision | Laser cleaning allows for precise control over the cleaning process, ensuring that only the targeted contaminants are removed without damaging the surrounding material. |

| Environmentally friendly | Unlike traditional cleaning methods that produce harmful waste and emissions, laser cleaning is a clean and eco-friendly process that does not generate any hazardous byproducts. |

| Time-saving | Laser cleaning is a fast and efficient method for removing contaminants from metal surfaces, reducing the time and labor required for automotive restoration projects. |

Applications of laser cleaning in automotive restoration

Laser cleaning can be used in a variety of applications within the automotive restoration industry. Some common uses include:

| Application | Description |

|---|---|

| Rust removal | Laser cleaning is an effective way to remove rust from metal surfaces, restoring them to their original condition. |

| Paint stripping | Laser cleaning can quickly and efficiently remove old paint and coatings from automotive parts, preparing them for refinishing. |

| Surface preparation | Laser cleaning can be used to prepare metal surfaces for welding, painting, or other restoration processes, ensuring a clean and smooth finish. |

Conclusion

Laser cleaning plays a crucial role in the automotive restoration industry, offering a safe, efficient, and environmentally friendly method for restoring classic cars and vintage vehicles. With its precision and versatility, laser cleaning has become an indispensable tool for automotive enthusiasts and restoration professionals alike.

#laser #cleaning #automotive #restoration #industry

słowa kluczowe: laser cleaning, automotive restoration, rust removal, paint stripping, surface preparation

frazy kluczowe: laser cleaning in automotive restoration, benefits of laser cleaning, applications of laser cleaning, environmentally friendly cleaning method.

- Laser cleaning for removing paint from surfaces - 12 May 2024

- How to choose a contractor for your project - 12 May 2024

- Fixed price or time and materials – what to choose? - 28 November 2023